Bubble Gum Process

Ever wonder how bubblegum is made? Get the full history and 'making of' right here! Subscribe to Discovery UK for more great clips: more. 4 Steps to Make Bubble Gum: Many manufacturers of chewing gum and gumballs choose to keep the specific ingredients of their sweet confections a secret. Yet, the process for making gum is standard throughout the industry.

1. Preparing the Gum Base When natural rubber is used as the gum base, it must first be harvested and processed. Sapodilla trees are scored with a series of shallow Xs, which.

Chethan Kumar on LinkedIn: PROCESS OF MANUFACTURING BUBBLE GUM🍬🍬 The ...

Rachel Weitzman Once the gum has finished seasoning, the individual sticks are wrapped in aluminium foil or wax paper, and placed in their proper packaging and shipped off to stores across the nation. For those of you wondering how is bubblegum made, most people don't like the fact that it is made from latex sap or a combination of chemicals. Whether you love it or hate it, there's no denying that the sticky treat known as bubble gum is an iconic part of American culture.

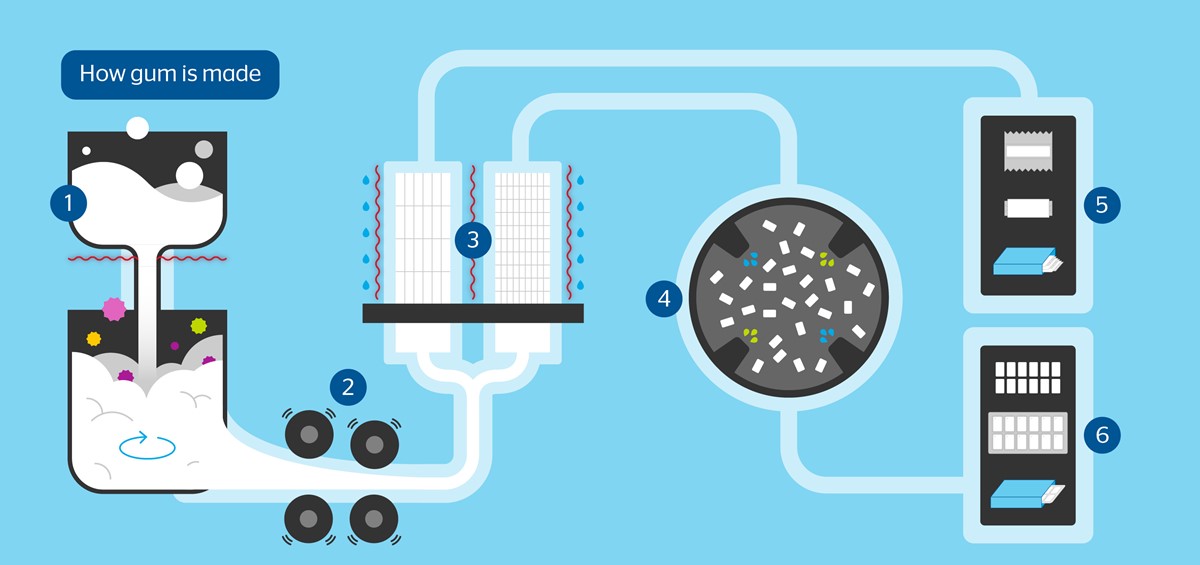

But how is it really made? The Manufacturing Process While the specific ingredients in gum might be a secret, the process for making gum is not. The first chewing gum making machine wasn't even patented, and today the procedure is considered standard throughout the industry. Preparing the chicle 1 If natural latex is to be used, it must first be harvested and processed.

How to produce chewing gums: Watch the video.

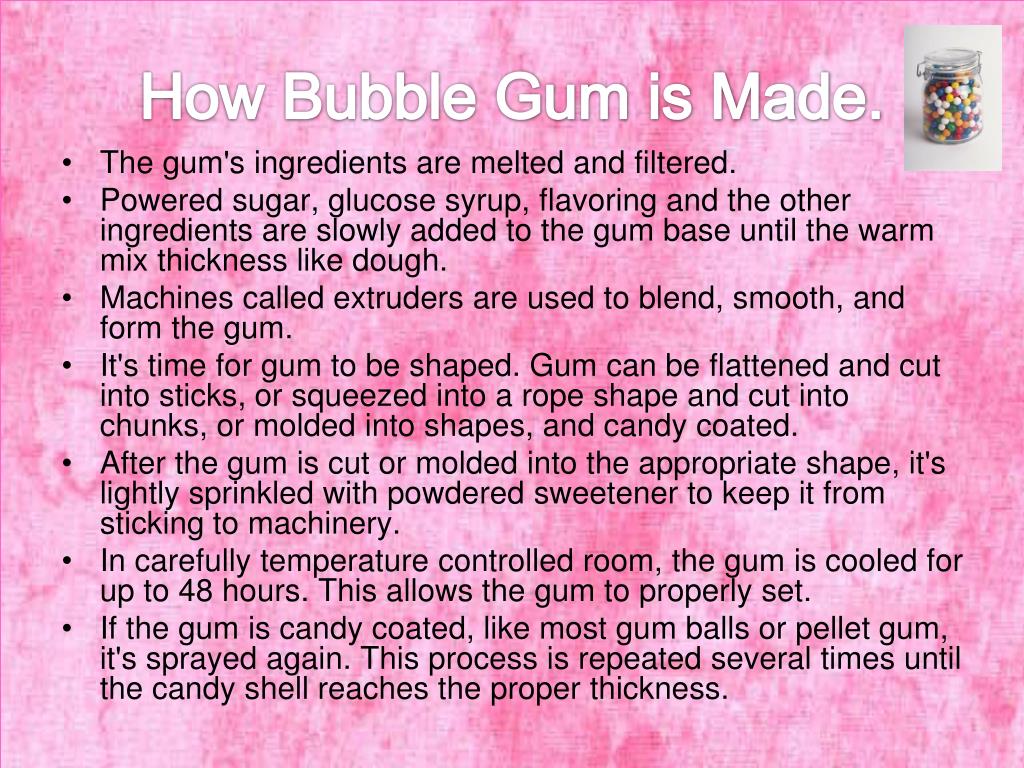

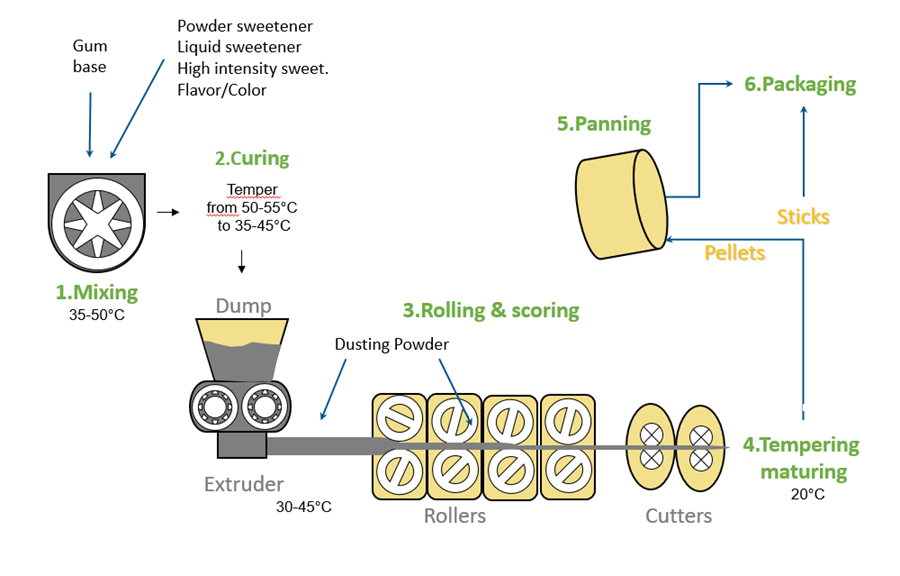

The process of making bubble gum involves a careful balance of base ingredients, flavorings, and packaging to create a product that is both delicious and visually appealing. The recipe for bubblegum is in the name - gum, or better said, natural rubber. Mixed with resins and oils, it forms the basic mass, the so-called base.

GUM FACTORY WORKER: "The main ingredients of chewing gum are the chewing gum mass or base, with sugar, glucose syrup, humectants, glycerine and flavoring. The bubble gum manufacturing process involves several key steps including ingredient preparation, mixing, kneading, rolling, flavoring, shaping, packaging, and quality control. Main ingredients consist of gum base, sweeteners, flavorings, colorants, softening agents, and corn syrup.

Odd Shape Toffee&Candy&Bubble Gum Forming Production Line

The final product is packaged and ready for distribution to consumers. All types of chewing gum are made the same way. The gum base for bubble gum is more rubbery to make it stretch without tearing.

For candy-coated gums, there is an additional process. Gum balls are soaked in a sucrose solution, dried, and rubbed with beeswax. Gums with liquid centers are filled with sweet liquid candy.

Standards for raw materials are high. Ingredients are inspected and tested. Curious about how bubble gum is made? Join us as we take you behind the scenes of the gum manufacturing process! From molding to packaging, you'll see each step of how bubble gum is produced.