Cold Dye Process

Conclusion Cold process dyeing opens up a world of creativity accessible for beginners eager to explore textile art dynamics without overwhelming technicalities or equipment requirements. With just a few basic materials and techniques at hand, you can create stunningly beautiful fabrics that reflect your personal style and artistic vision. Let's review how to cold water dye clothes.

Dying a piece of clothing can put a whole new spin on your look. Renew some of your clothes with fresh, vibrant color, or dye some whites to give them more flavor. Simply follow these step.

Dyeing Recipe and Process of Cotton Fabric with Cold Brand Reactive ...

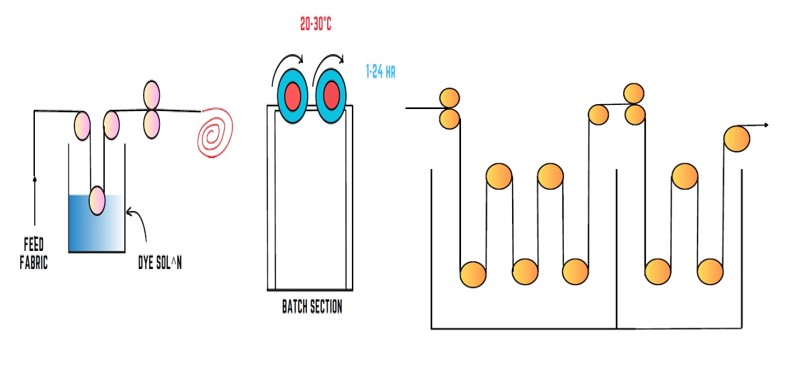

Cold pad batch (CPB) is a method of dyeing textiles, typically cellulosic fibers such as cotton, in which the textile is impregnated with dye in a cold state, rather than being heated. High dye fixation and no thermal energy are the advantages of the CPB process. [1] CPB-dyed fabrics are less expensive, have a softer hand feel, and have a cleaner surface than exhaust dyed materials.

The. The garments are dyed as ready. Soda Ash: Because this is a cold dyeing process, you must first pre-treat your fabric in a soda ash bath.

Cold Pad Batch CPB - A Sustainable Dyeing Process For Woven and Knit ...

This is a super important step! More later Jaquard Procoin MX powder dyes in a variety of colors Ice (yes, captain obvious!) You will probably get through about 10 dish towels with one large bag of ice. The excess dye from the dyeing process can be reused with the same intesity. Color sets on the fabric by oxidation in contact with air.

The suitable products for cold dyeing method are: Acquerello and Tempera. Tempera is a unique shade color and cannot be diluted in water. It's specifically designed to create defined patterns and shapes.

Stages of Dyeing in Textile | Theory of Dyeing - Textile Learner

This prevents uneven dye application. Apply Dye: Use a brush or other suitable paint tools to apply the cold dye to the dry fabric. You can use various techniques to achieve different looks, such as: Solid color application Brush strokes for a painterly effect Sponging or stippling You can use various techniques to achieve different looks, such as.

Now a days this process widely used in our Woven dyeing industry and it is a development process for Knit dyeing industry in Bangladesh. It is primarily a cold method where the dyeing temperature is 20-25°C and use Cold to Medium Brand Reactive Dyes, and so it is called Cold Pad Batch (CPB) Dyeing. Fiber reactive dyes are cold water dyes that are fixed chemically, instead of with heat.

Hence the alternative name for them, "cold water dyes" or "color process dyes." No heat, means no stove, hooray! This unique property sets fiber reactive dyes apart from other types of dye and makes them queen of home tub dyeing, batik, and tie dye. The cold pad batch (CPB) dyeing process is a continuous (semi) process and efficient dyeing method. The cold pad batch (CPB) dyeing technique actively dyes cellulosic fibers like cotton, viscose, and their blends.