What Is Hot Rolled Sheet

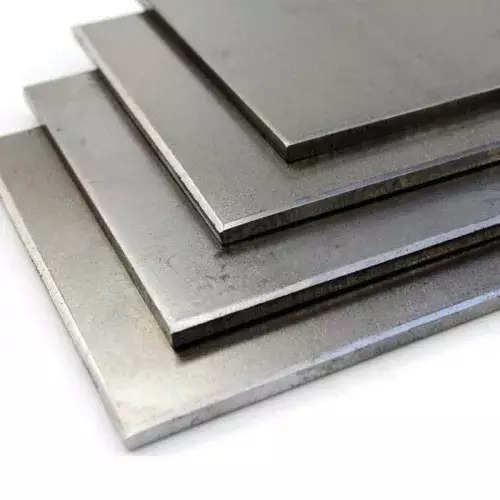

When comparing hot rolled vs cold rolled steel tensile strength and yield strength, cold rolled steel generally performs better due to the strain hardening that occurs when the steel is worked at or near room temperature. What is cold rolled steel? Cold rolled steel is simply hot rolled steel that has been through further processing steps. Understand what hot rolled steel sheet is, its key properties, advantages, and common applications in construction and manufacturing industries.

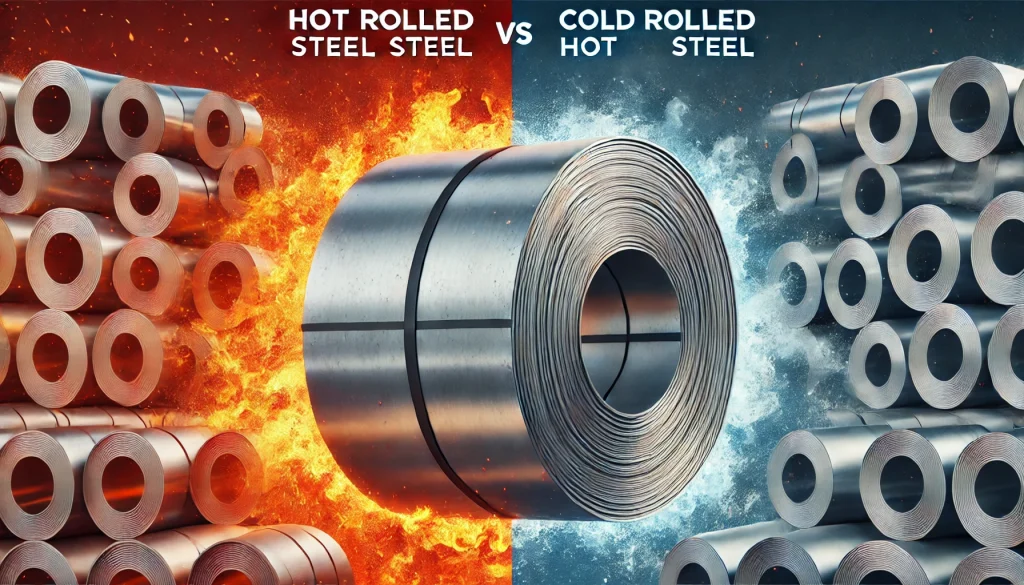

Hot rolled vs. cold rolled steel - what's the difference? From physical properties to best-use cases, here's a comparison guide on these steel types. Hot rolled steel and cold rolled steel both have their uses and advantages deriving from their respectibe manufacturing methods.

What Is Hot Rolled Sheet at Audrey Stier blog

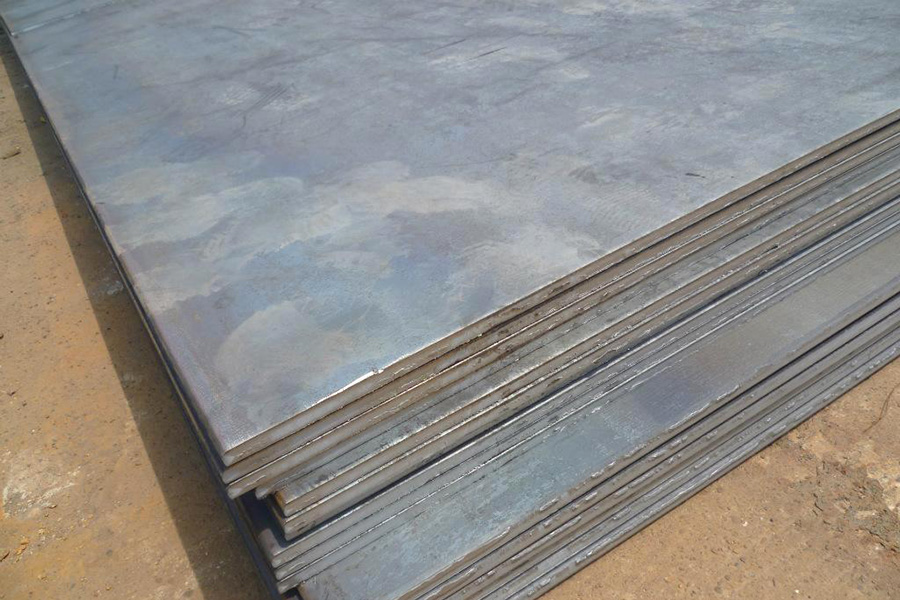

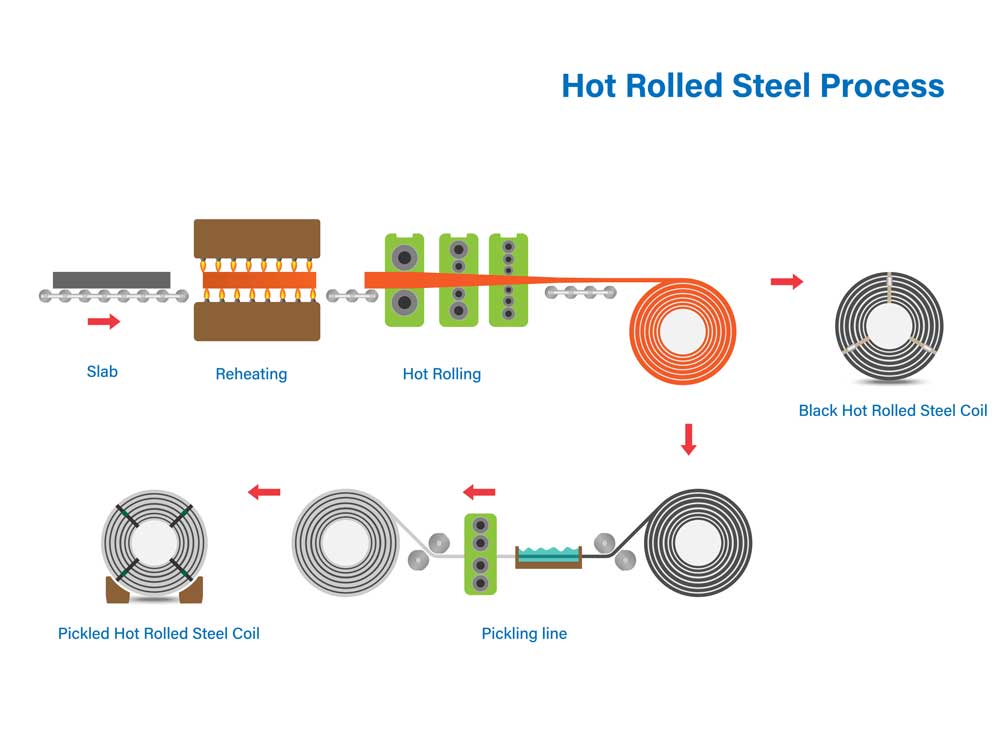

Hot rolled steel products offer a perfect blend of strength, versatility, and cost. What Is Hot-Rolled Steel? Hot-rolled steel is produced by rolling steel at a high temperature, typically over 1,700°F (926°C), which is above the steel's recrystallization temperature. This makes the steel easier to shape and form.

Once the steel cools, it shrinks slightly, which can result in less precise dimensions compared to cold. A good understanding of steel grades will help you make the best choices for your project. about hot rolled vs cold rolled steel.

Hot Rolled Sheet | Steel Sheets & Plates | Harris Steels Ltd

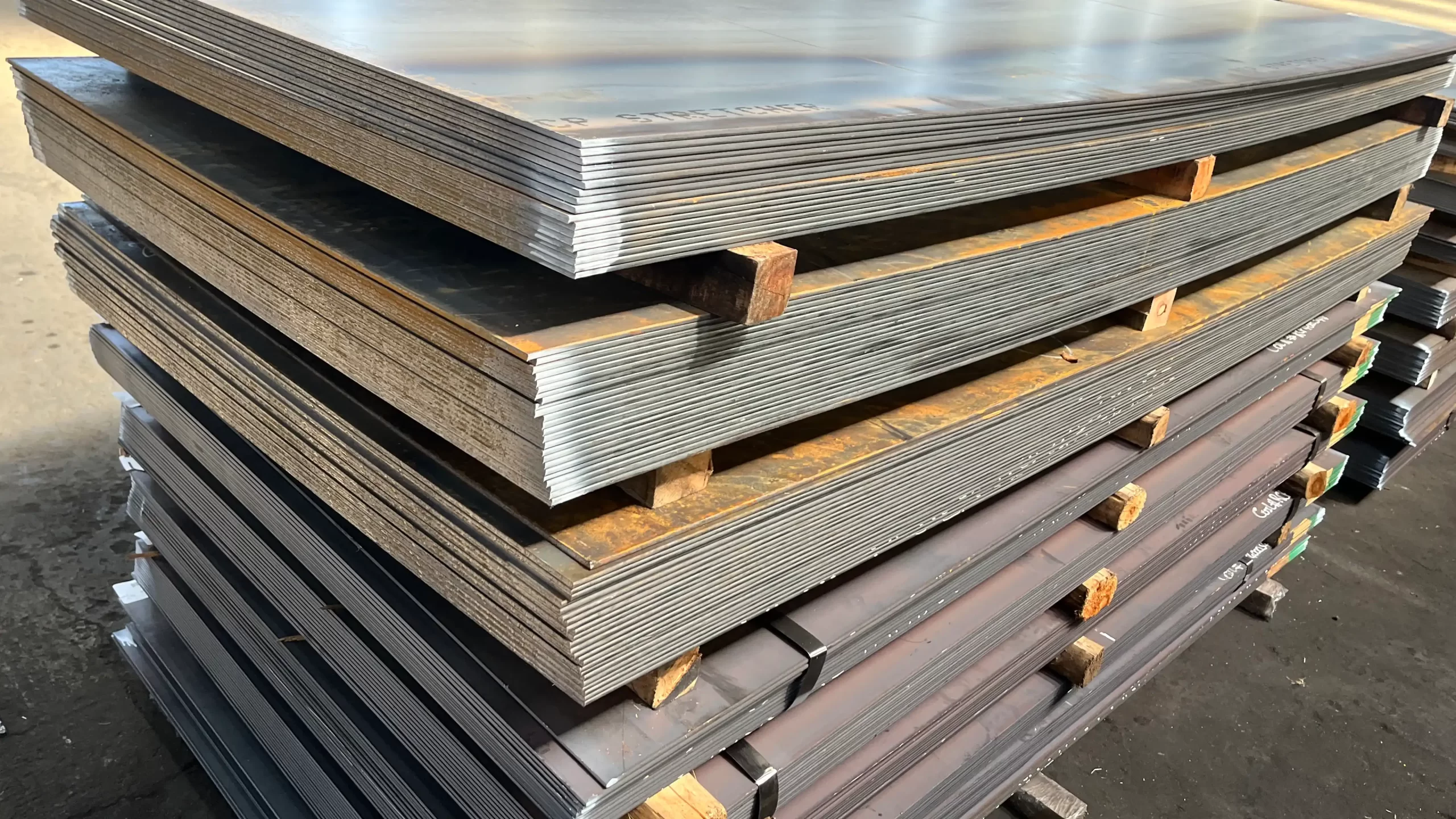

Hot rolled sheet is a foundational material widely used in construction, automotive, and manufacturing industries due to its durability, versatility, and cost-effectiveness. Produced through a high-temperature rolling process, it offers superior malleability and is ideal for structural components that demand strength without precision shaping. Cold-Rolled Steel: Rolled at room temperature from hot-rolled coils.

Typically involves pickling to remove scale, followed by multiple cold-rolling passes to achieve desired thickness. Work hardening occurs during rolling, often requiring annealing to restore plasticity. Hot-Rolled Steel: Rolled at high temperatures (usually above 1000°C).

Coil Sheet Metal Guide: Hot-Rolled vs. Cold-Rolled Options Explained - Hungthai Metal Corporation

Rolled steel sheets and plates are a staple in manufacturing, known for their versatility, cost-effectiveness, and suitability for bending and other forms of fabrication. This blog post aims to unravel the complexities of rolled steel sheets, delving into the characteristics, applications, and types of these essential materials.