Soft Jaws Drawing

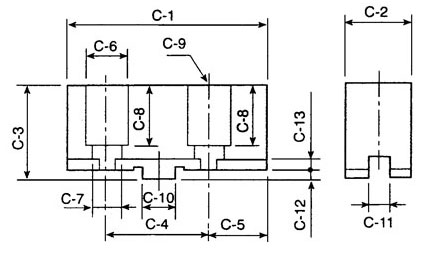

A library of engineering drawings for current and legacy Kurt Workholding products with CAD, 2D and 3D files of most products. Drawing plans and dimensions to make a set of interchangeable soft jaws. This project is meant to be made with a lathe and mill.

Course 3 - Haas and Autodesk Fusion - Drafting, Soft Jaw Design, and Programming Learn the basics of blueprint creation in Fusion, importing a vise and soft jaw blanks, creating soft jaws for Operation 2, program toolpaths and documentation for the soft jaws, and setup and machine the soft jaws to prepare for OP2. Fabricating soft jaws takes time and labor. Engineers and machinists have to first CAD the design and then take the design to program for machining on their CNC using CAM software.

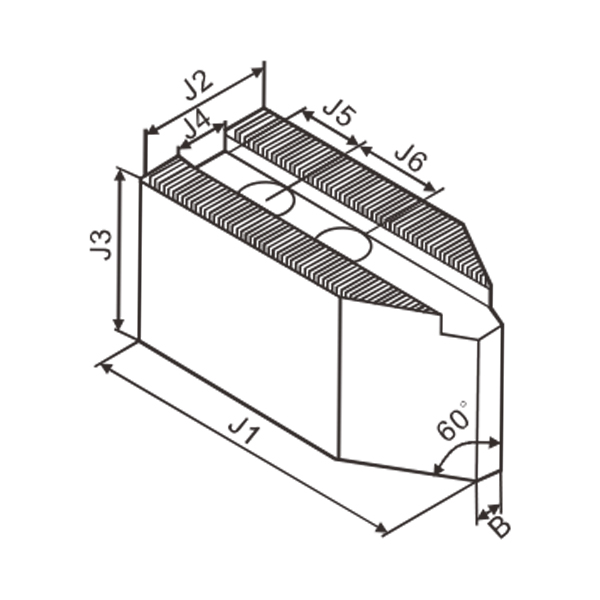

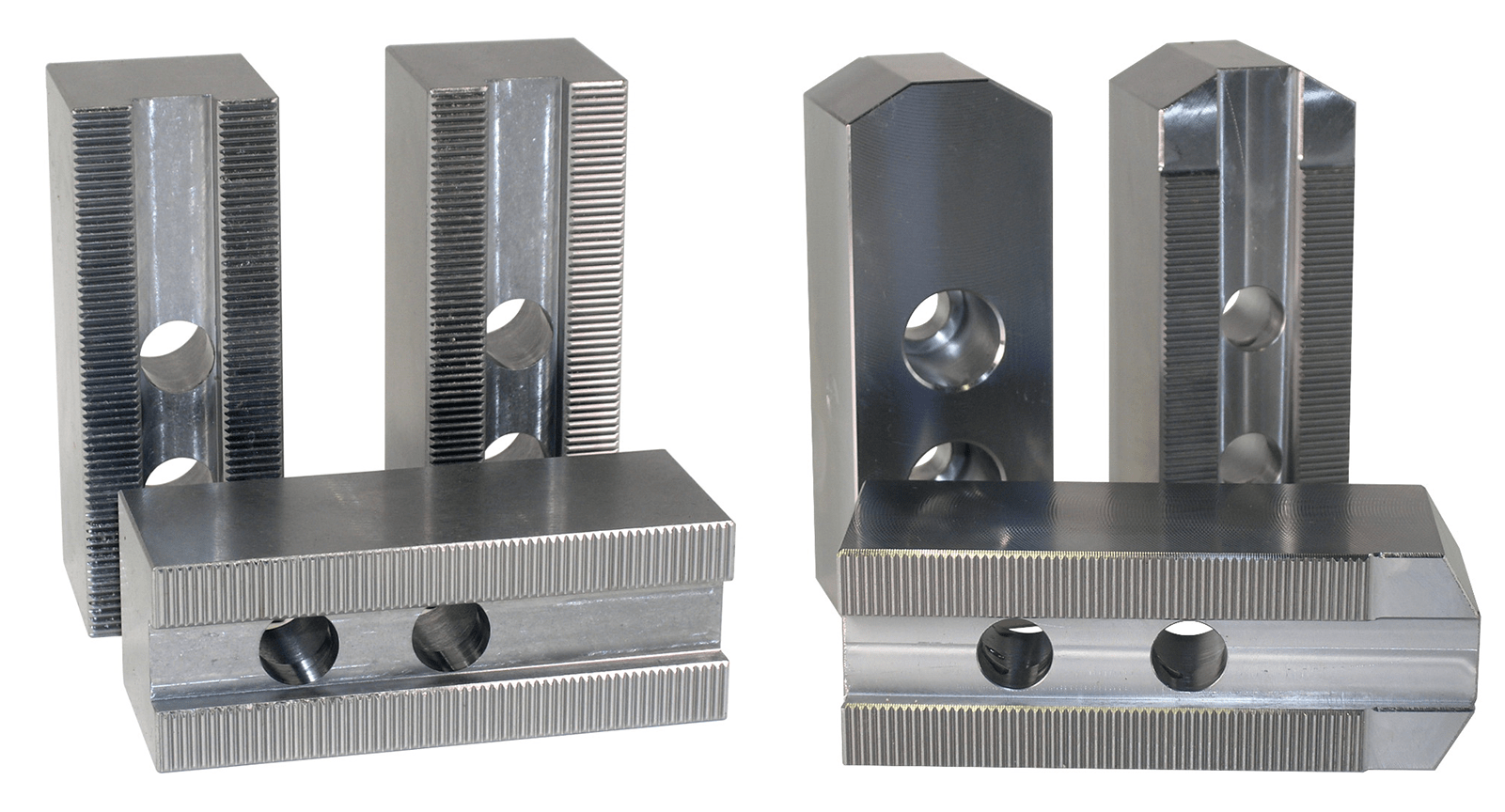

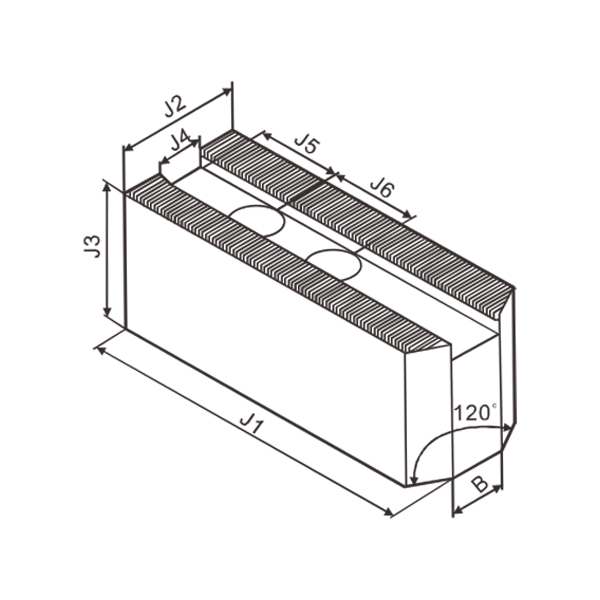

Soft Jaws Soft Jaws set for 02SK type 3-Jaw Chuck (3-Jaw Powerful Scroll Chuck)

This is one of the most time-consuming steps in creating soft jaws. They then can finally fabricate the soft jaws, and then may have to make small modifications. Best of all, the drawing for this great product is FREE! Once you own the drawing, make your own soft jaws and as many as your shop needs.

Download the free drawing at the Pierson Workholding Website. Quick flip design provides 4 useable sides per jaw; 2 on top and 2 on bottom. Improved Machining Accuracy: Machined soft jaws ensure concentricity and repeatable positioning.

How to Design Soft Jaws in SOLIDWORKS - YouTube

Compatibility with Various Chucks: Standard soft jaws fit common three-jaw or four-jaw chucks, suitable for CNC and conventional lathes. Do you know if the shape of your soft jaws could make or break your part? In this episode of How We Do It, Shawn from dives into the details of designing soft jaws and why the profile shape really matters. From tips on preventing part pullout to improving accuracy and avoiding damage to your parts, Shawn breaks it all down in a simple.

LATHE_Cut Soft Jaws Cidronek December 8th, 2015 is usefull for cutting internal of soft jaw in CNC Lathe for 250mm Diameter Chucks Download files Like Share 742 Downloads 35 Likes 3 Comments. Starter Kit Download Solid Model (STEP) Vise Base Download Solid Model (STEP) Soft Jaws 2X3 Soft Jaw Typically used in a set of 3 for double. Module overview In this module, you set up soft jaw blanks on a vise and cut soft jaw geometry to be used for operation 2 of the brake caliper.

LONG) ALUMINUM SOFT JAWS FOR 6 KURT VISE

After completing this module, you'll be able to: Assembly soft jaws on a vise. Set up the WCS on soft jaws. Load and verify a CNC program.

Machine and verify soft jaws.