Sheet Dyeing Process

Slasher Dyeing is also called sheet dyeing. It is a continuous process which combines dyeing and sizing in a single operation. Warp yarns are repeatedly passed in warp beam form through several baths of indigo dye before being sized and wound for weaving.

The dyeing time is deliberately short to allow poor dye penetration and build. Different fabrics react differently to various dyes, so it's important to pick a dye that's suitable for the specific fabric of the sheet. Cotton, for example, may require a different type of dye compared to silk or polyester.

Fabric Dyeing Process with Colorful Array Stock Image - Image of creativity, cloth: 318107913

Understanding the fabric's composition is necessary for a successful dyeing process. Dyeing your own sheets at home is easy and fun, and you can even create your very own custom color by mixing different dyes! Use 1-2 boxes of dye if you want to dye one of your sheets a solid color, or use multiple colors if you're looking for how to tie-dye bedsheets! They also use a more energy-efficient process than conventional dyeing, capturing and reusing water during the process. It's not just our dyes and our process that passed the test, but every part of the product, from the zipper right down to the trimming.

The cost of the dyeing process both in terms of dyes, equipment and processing times, greatly impact the profitability of a manufacturing company. Other key factors considered when selecting dyes include ease of mixing with other dyes and chemicals, uniformity or level dyeing properties, dusting issues when using powdered dyes, and overall. Dyeing is the process of adding color to textile products like fibers, yarns, and fabrics.

Textile Dyeing and Finishing: Four Processes and Common Equipment

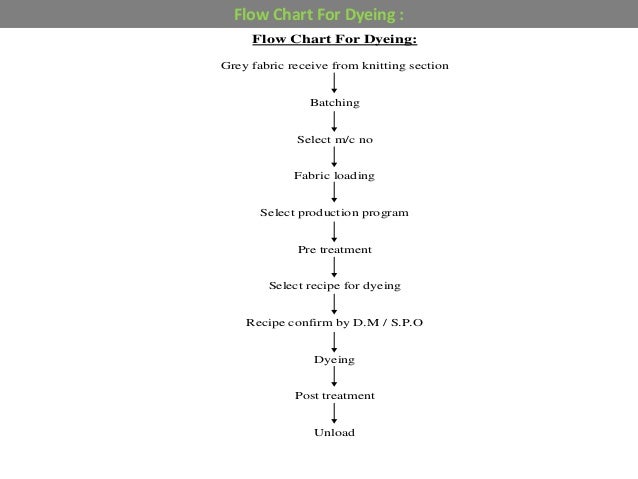

Every textile product has a unique dyeing flow chart. Such as fiber dyeing flow chart, yarn dyeing flow chart, fabric dyeing flowchart, etc. In this article, I will show the fabric dyeing flow chart.

It is also called the common flow chart of dyeing. In previous, we have discussed flow chart of woven. Learn the complete dyeing process in textile industry.

Sheet Dyeing Machine - Indigo PWP Multi Color Sheet Dyeing for Denim

From fiber preparation to color fixation, discover methods, challenges, and innovations. Rope Dyeing Vs Slasher (Sheet) Dyeing This is a guest post by Harry Mercer Until 1915, most Indigo dyeing was conducted in skein machines for cotton or loose fiber dyeing for wool. Skein dyeing of Indigo is still the best method for dyeing Indigo on very fine yarns for the delicate high.

The following table gives you a comparison of the possible processing stages such as: 1- Indigo rope dyeing process 2- Indigo one sheet dye slashing 3- Indigo double sheet dyeing 4- Loop dye 1 for 6 (continuous dye slashing) 5- Loop dye 1 for 6 with dyemer (continuous mercerization dyeing and sizing). The dyeing process for different textile materials could be different, but the basic idea is the same for all. For all types of dyeing, pre.