Pattern Colour Code In Casting

Explore casting patterns: follow board, loose piece, skeleton, match plate, split patterns, and pattern color codes for efficient mold making. In this tutorial students can learn " PATTERN COLOR CODING - pattern colour" If any query or suggestion then comment below. And don't forget to support me by like, subscribe and share.

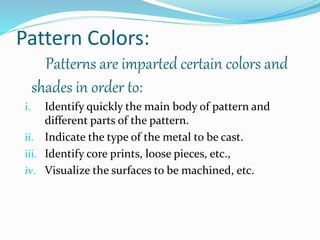

Why colour coding of patterns is required in casting? To get the best result from the pattern, the pattern maker needs to mark the pattern with a different colour to indicate the exact function of every part of the pattern by colouring the pattern. Patterns are coloured to provide visualization of the machined surface and identification of the main body. Color coding for the casting material to be used or identification of particularities to be observed during molding On the one hand, the identification of a pattern is accomplished by means of a pattern number forming the link between the pattern and the accompanying documentation; on the other hand, the color coding according to EN 12890.

Colour Coding of Pattern In Casting | Pattern Colour Codes | Core ...

Explanation: Pattern: Pattern is the replica of final casting to be produced with some modification. Modification are done in the form of allowances. Pattern Colour Code: The pattern are normally painted with contrasting colors such that the mould maker would be able to understand the functions clearly.

The colour code used is as follows. The types of pattern used for a specific application depends primarily on the number of castings required, the moulding or casting process to be used, the size of the pattern and the casting tolerances that are required. In this article, you'll learn what are different types of patterns and pattern allowances used in casting.

color_pattern_image

In addition, you can also download the PDF file at the end of this article. What is a Pattern? Patterns are colour coded to quickly identify key parts like the main body and loose pieces, visualize surfaces to be machined, and indicate cast surfaces that require or avoid machining. According to the American scheme, black indicates unmachined cast surfaces, red shows surfaces to be machined, red strips on yellow identify loose pieces and seats, yellow marks core print seats, and black.

The objective of the procedure is to define colour coding to be followed for various parts of Pattern Equipment. This enables in proper storage and in preventing mixing up of different patterns and provides information on location of gating, risering etc. for moulding operations.

Manufacturing Processes | PPT

1. PATTERN MAKING Introduction, Objectives, Pattern Materials, Pattern Making Tools, Pattern Allowances, Types of Patterns, Colour Coding for Patterns and Core Boxes.