Hot Rolled Steel Description

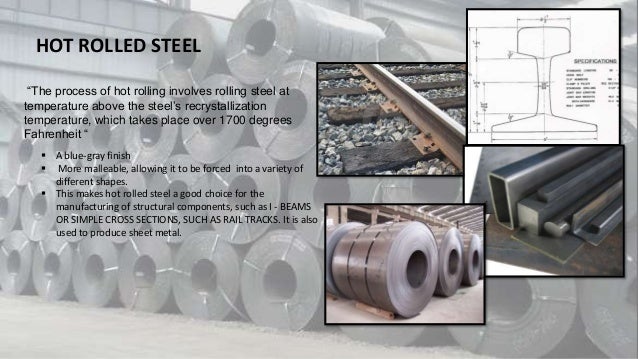

From construction to manufacturing and beyond, hot rolled steel is utilized in countless industries for producing top. Cold rolled steel, on the other hand, starts as hot rolled steel but undergoes additional processing at room temperature, including annealing and temper rolling, which enhances its strength, hardness, and surface quality. Rolling is a critical stage of steel processing where steel is passed through pairs of rollers, reducing its thickness and shaping it into products such as sheet, plate, and beams.

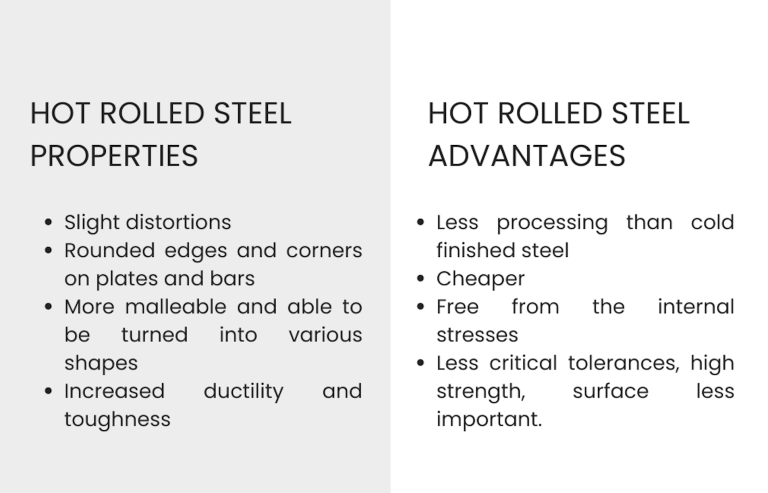

There are two main types of rolled steel: hot rolled and cold rolled, each with different characteristics and operational challenges that occur during production. The characteristics of hot rolled steel are defined by its mechanical properties, which include high ductility, good weldability, and moderate strength. The hot rolling process also imparts a rough surface finish, which can be beneficial for certain applications but may require further processing for aesthetic purposes.

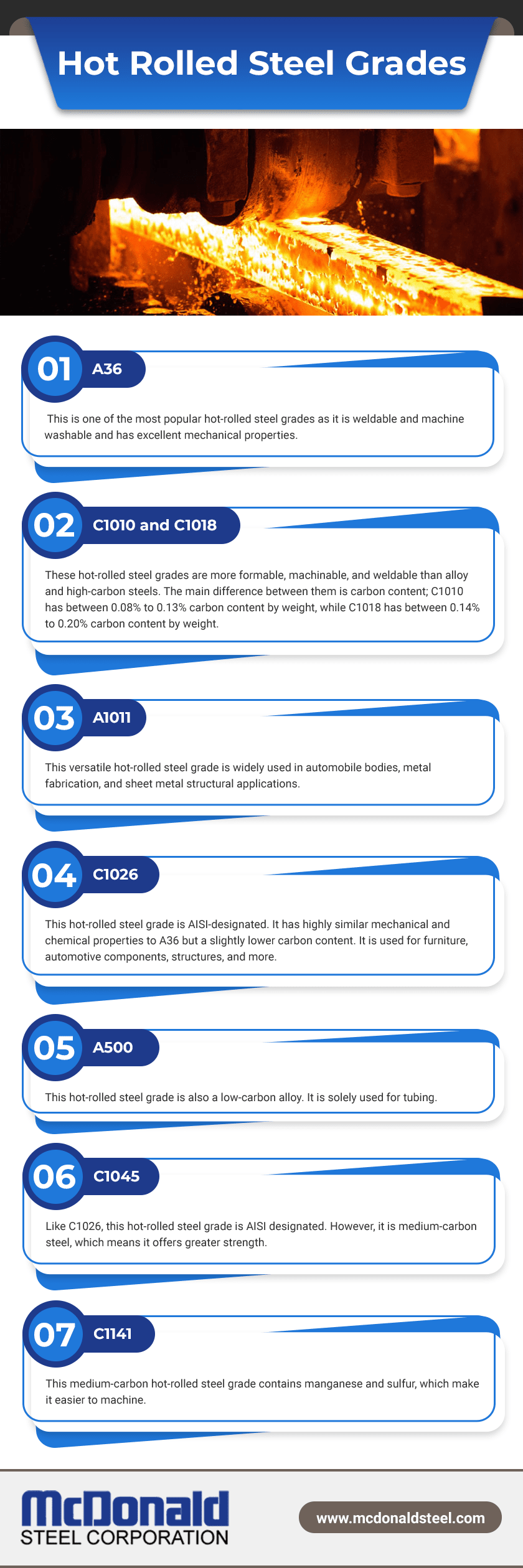

A36 Hot Rolled Steel Properties

Hot rolled vs. cold rolled steel - what's the difference? From physical properties to best-use cases, here's a comparison guide on these steel types. Explore the key characteristics of hot rolled steel versus cold rolled steel.

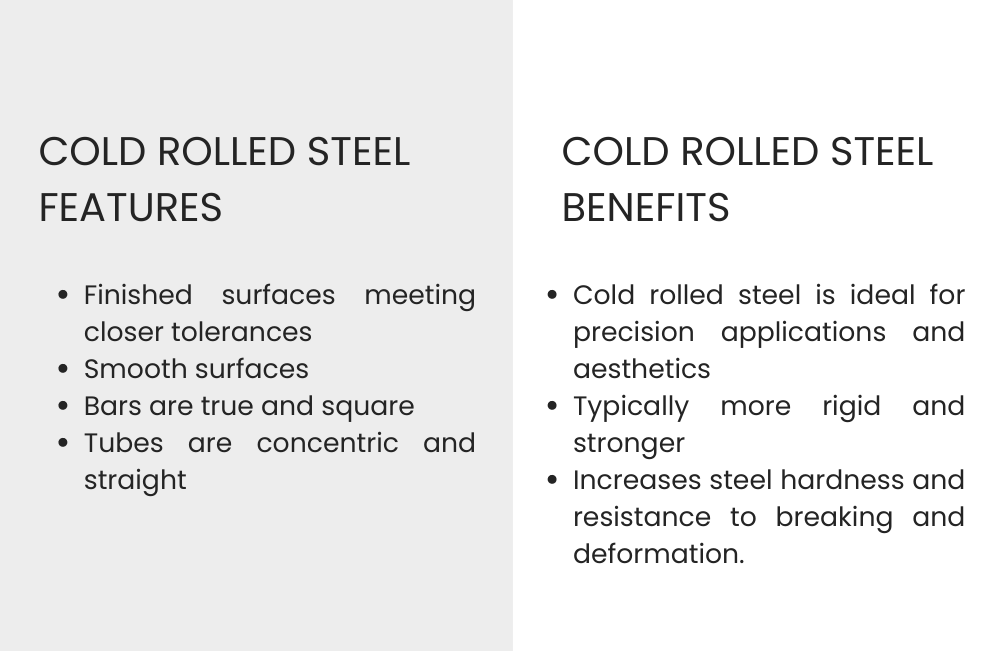

Understand their differences to determine which is most likely hot for your project needs. Hot rolled steel is an essential material in the construction and manufacturing industries, known for its strength, durability, and cost. Cold-rolled steel is hot-rolled steel that has been further processed at room temperature to increase its strength and surface finish.

Hot Rolled vs Cold Rolled Steel - YouTube

It undergoes compression between rollers in a cold-reduction mill, which reduces thickness, refines shape, and improves surface properties. A good understanding of steel grades will help you make the best choices for your project. about hot rolled vs cold rolled steel.

Hot rolled steel is produced at high temperatures, making it more cost-effective and ductile but with lower dimensional accuracy and a rougher surface finish. Cold rolled steel undergoes additional processing at room temperature, resulting in tighter tolerances, higher strength, and a smoother, cleaner surface, albeit at a higher cost.