Flash Gold Color

Gold flash vs gold plating both enhance the performance of electronic components, but they differ in thickness, cost, durability, and electrical conductivity. Learn about their key differences, common applications, and which option is best suited for your needs in this comprehensive guide. In the electronics industry, "gold" is often used on the surface of products.

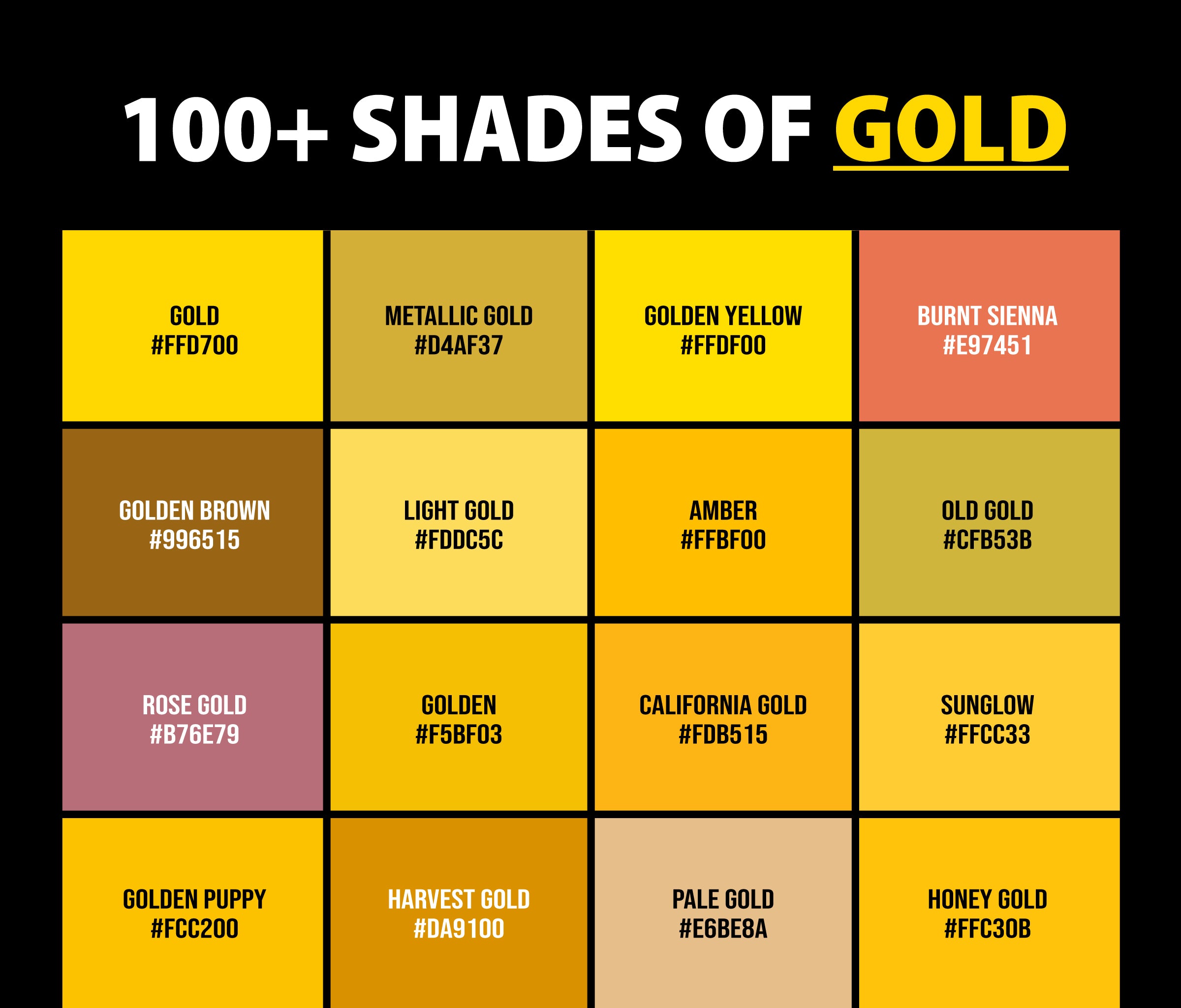

But do you know what hard gold, soft gold, electroplated gold, ENIG (Electroless Nickel Immersion Gold), and flash gold are in printed circuit boards? What are the differences between them, and what should be considered in their applications? Gold flash: A short plating cycle (less than 15 seconds) that is used for color or thin deposits of less than 3 mils. A flash allows the plater a quick and inexpensive way to have a variety of gold colors (14kt. to 24kt.) as a final finish.

Flash Gold Metallic Metal Paints and Metallic Paints - ME164 - Flash ...

Green gold: A colored gold finish that has a slight green hue due to the addition of silver as an alloy. The current density of the gold process is typically 20 amps per square foot which is manageable for a thin coating. Figure 2.

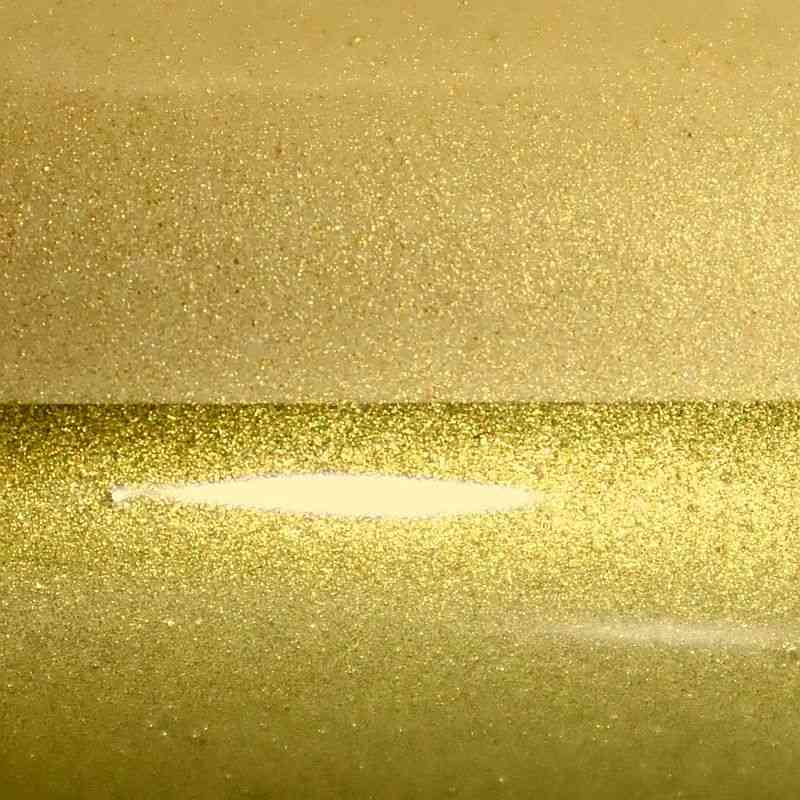

Flash gold plating is a super-thin electroplated gold layer. It's around 3-5 microinches (0.076-0.25 microns) that are placed on connector contacts and pogo pins. Flash gold plating provides corrosion resistance and electrical conductivity at a far cheaper material cost than platinum plating.

FLASH Acrylic Metallic Colour 24 Carats Gold (Code 100) 50 ML : Amazon ...

Adding a thin gold layer to your connector or pogo pin works as the best answer for controlled. Most connectors are electroplated in an acid hard gold first. This gold is an alloy and offers better mechanical wear protection.

Then a flash of 24 kt cyanide gold to give it an even color. Richard Bancroft - Carrum, Vic, Australia 2005 publicly reply to Richard Bancroft A. Flash gold plating is less than 0.25 Microns and usually not done on.

Sumica Super Flash Gold 41665 | Sudarshan Chemical Industries Limited

Semi-Opaque colors have good hide, three coats are recommended for best results. Sheer colors are translucent overcoats that when viewed from various angles flash color and/or give luster to traditional paints, other Metallic Paint colors or faux finishes. Discover FlashGold-Evo, a safe and sustainable flash gold plating process, cyanide-free and nickel-free, ideal for jewelry and fashion accessories.

This beautiful Metallic Metal Paint Color shade is called Flash Gold, and comes from a company called Modern Masters. Their product number, along with the HTML color code, RGB, and CMYK codes are listed below. The unique flash plating process ensures a smooth application, providing a luxurious look while maintaining cost-effectiveness.

Perfect for artisans and manufacturers seeking high-quality results, LEGOR is a reliable choice for adding a touch of elegance to your designs. Experience the brilliance of gold with LEGORs trusted craftsmanship!